The Internet of Things (IoT), which is enabling increased connectivity of everyone with everything, everywhere and every time, is causing a fundamental shift in how we do things. IoT is mainly divided into two different segments; consumer and industrial IoT. Indian industrial IoT segment is currently valued at US$1 billion and internationally it is expected to be 3 Trillion US$. IoT is populated by technology startups who have traditionally focused on mature western markets. There are 120+ firms and more than 60% are startups amongst them and they have technical skills and knowledge ready for the next IoT revolution. But when it comes to Industrial IoT implementation there are various myriad questions revolving around it. Questions such as “What type of analytics should I use”, “Who is going to manage my data?” “How will IIoT impact my IT infrastructure and budget?”. All these questions and concerns are reasonably valid but just as there are many high-level issues as much as issues at the device level, that need to be addressed.

In Indian markets, where every manufacturing or product assembly company will have several types of PLC/Gateways mounted with each one having its own communication protocol, where every organization struggles when it comes to gathering the data on a common machine and there every IoT or an automation company will have a challenge of connecting disparate devices from multiple manufacturers is a key first step to creating the IIoT and is made possible through protocol conversion. Wikipedia describes a protocol conversion as “a device used to convert a standard or proprietary protocol of one device to the protocol suitable for the other device or tools to achieve the interoperability.” The major protocol translation messages involve the conversion of data messages, events, commands, and time synchronization. Connecting your new machines and legacy machines is a need of an hour if not now then in immediate near future every manufacturing company has to do it for increasing efficiencies along with collecting, analyzing, developing data and for reducing the downtime.

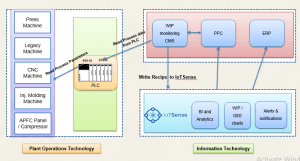

Industrial IoT can help organizations integrate, connect PLC’s, SCADA to collect and process data in real time basis to control devices and applications directly affecting current ongoing operations. IIoT enables organizations to improve productivity and increase operational efficiencies through real-time device connection and data processing. Creating a network of both legacy machines and new machines through PLC/Gateway devices, organizations can extend the equipment/machine lifespan, they can improve their current processes, they can track their product development with real-time dashboards, can set thresholds, alarms, alerts and can get notification on there email or phones when needed also it will surely help them to increase their OEE and if they want they can push this data on the edge/cloud as well.

Solution architecture for reference.

The ideal partner for a successful Industrial IoT implementation at factory premise.

Winjit is a fast-growing provider of software consultancy, design and development services, headquartered in India. With state-of-the-art delivery centers in India, we have a team of competent professionals with expertise in different technologies. Our development centers have all the necessary communication links and hardware/software for the development of commercial applications, web portals, and websites. To maximize value for the customer, our development centers follow ISO 9001 certified processes. Our Project Management Methodologies are a blend of the finest practices tuned to support the engagement models. The idea behind using IoT tools in the manufacturing industry is to attach sensors to their devices and collect data from customers. This data can be used to guide the industry not only to analyze how their products are being used but they also determine the usage patterns and it will help them to improve productivity, flexibility, and responsiveness to changes in their customer demands along with cost reduction. Predictive maintenance approaches minimize unscheduled downtime, improves maintenance, productivity, and effectiveness, and enables optimal asset performance.